How Polyester Threads are Dope Dyed

The dope dyeing process starts with melting the polyester polymer chips in a heated extruder. Then, a masterbatch colorant is added to the melted polymer. A masterbatch is a concentrated mixture of pigments and additives that gives the desired color and properties to the polymer.

The colored polymer melt is then extruded through spinnerets, which are tiny holes that shape the polymer into fine filaments. The filaments are cooled, solidified by air or water, and then collected on spools or bobbins. The resulting threads have uniform color throughout their cross-section and length.

Benefits of Dope Dyeing

Dope dyeing has many advantages over traditional dyeing methods, such as:

- Sustainability: Dope dyeing reduces water consumption by up to 90%, energy consumption by up to 30%, and carbon dioxide emissions by up to 40%. It also eliminates the need for dye baths, rinsing, drying, and wastewater treatment, which reduces chemical usage and pollution.

- Cost-effectiveness: Dope dyeing simplifies production and saves time and resources. It also reduces the risk of color variation, fading, and staining, which improves product quality and customer satisfaction.

- Performance: Dope-dyed polyester threads have better color fastness, UV resistance, abrasion resistance, and anti-pilling properties than traditionally dyed threads. They also have less shrinkage and more dimensional stability.

Conclusion

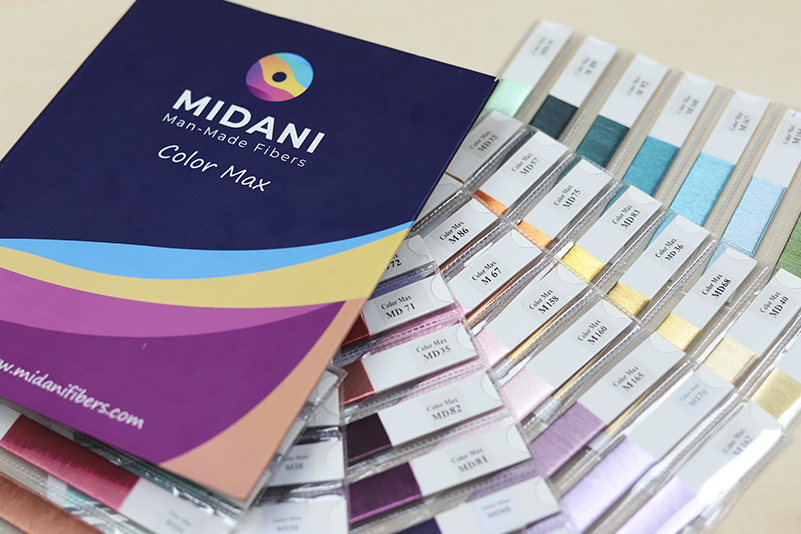

Dope dyeing is an innovative technique that can make polyester threads more eco-friendly and efficient. By adding color to the polymer melt before spinning, dope dyeing can save water, energy, chemicals, and money while enhancing product quality and performance.At Midani Yarns, we bring over 65 years of experience to everything we do, from how we pick our polyester PET chips to the machines we use to produce our ColorMax Polyester yarn.

Our expertise in the field allows us to constantly find areas of improvement and take our production to the next level, ensuring we exceed our clients’ expectations.

Ask about our ColorMax Polyester Line, Contact Us.