Polyester POY threads are one of the textile industry's most widely used synthetic fibers. POY stands for partially oriented yarn, which means that the yarn is not fully stretched and has some degree of twist. POY threads are mainly used for further processing, such as texturizing, dyeing, or weaving, to produce different types of fabrics and garments.

Different types and grades of polyester POY threads depend on their physical properties, such as denier, filament, luster, color, and tenacity. Denier is a unit of measurement that indicates the weight and thickness of the yarn. Filament is the number of individual strands that make up the yarn. Luster is the degree of shine or dullness of the yarn. Color is the hue or shade of the yarn. Tenacity is the strength or resistance to the breaking of the yarn.

The most common types of polyester POY threads are:

- Semi-dull POY: This type of POY has a low luster and a natural white color. It is suitable for dyeing and texturizing to produce various colors and effects.

- Bright POY: This type of POY has a high luster and a bright white color. It is often used for making shiny fabrics, such as satin or chiffon.

- Dope-dyed POY: This type of POY is dyed during spinning, meaning the color is embedded in the fiber. It has better color fastness and uniformity than dyed POY. It also saves water and energy consumption during the dyeing process.

- Micro-denier POY: This type of POY has a very low denier, usually less than 1. It is very fine and soft and can produce fabrics with a silky touch.

- High-tenacity POY: This type of POY has high strength and durability, which makes it suitable for making fabrics that require high performance, such as sportswear or industrial textiles.

Polyester POY threads have various applications in the textile industry, such as:

- Texturizing: This process adds crimp, curl, or loop to the POY to increase its bulkiness, elasticity, and softness. Texturized POY can be used for making knitted or woven fabrics with different textures and appearances.

- Dyeing: This process adds color to the POY by using dyes or pigments. Dyed POY can be used for making fabrics with different hues and shades.

- Weaving: This process interlaces two sets of yarns at right angles to form a fabric. POY woven fabrics can have different patterns, such as plain, twill, or jacquard.

- Knitting: This process loops one or more yarns to form a fabric. Knitted fabrics from POY can have different structures, such as jersey, rib, or pique.

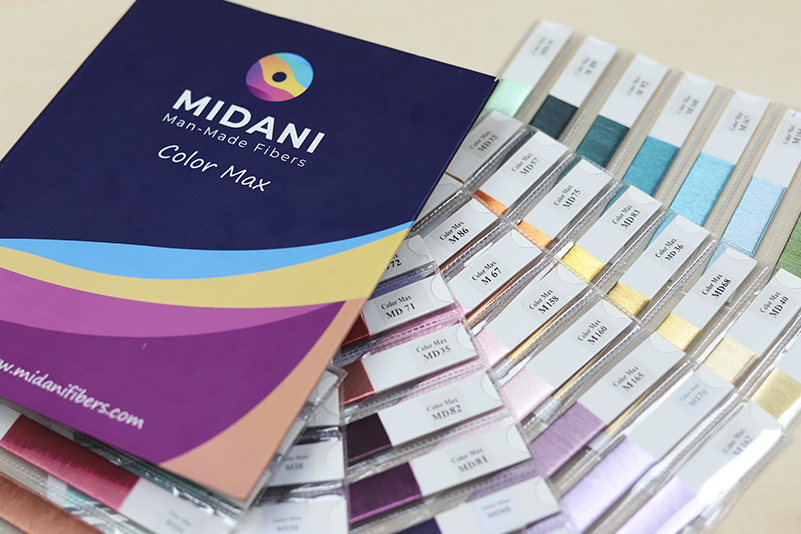

One of the advantages of polyester POY threads is that they can be customized according to the customer's specifications and requirements. For example, at Midani Yarns, you can find polyester POY threads in different deniers (from 50 to 600), filaments (from 24 to 288), and colors (over 200 colors). You can also choose between semi-dull, bright, or dope-dyed lusters. They are also flame retardant, UV resistant, antibacterial, and thermal resistant.

Polyester POY threads are versatile and economical synthetic fibers that can make various fabrics and garments with different properties and functions. They are also easy to care for and have good resistance to wrinkles, shrinkage, and abrasion.

Contact Us if you want to learn more about our ColorMax polyester POY lines.