How do we maintain international standards as Egyptian yarn producers?

Yarn is a long nonstop length of interlocked strands, reasonable for use in creating materials, sewing, stitching, weaving, or ropemaking. Thread is a sort of yarn planned for sewing manually or by a machine. Currently, sewing strings might be made with wax or different greases to withstand the anxieties of sewing. Embroidery strings are yarns explicitly intended for embroidery. The Egyptian yarn industry is ancient, tracing back to the age of the pharaohs. Egypt is on the turn for the better within the incorporated material industry in the Middle Eastern district. Egypt includes the entire creation process directly from the development of cotton to the creation of yarns, textures, and instant clothes. The yarn and attire industry is the second biggest industry, close to agriculture, and assumes a significant part in molding the Egyptian economy.

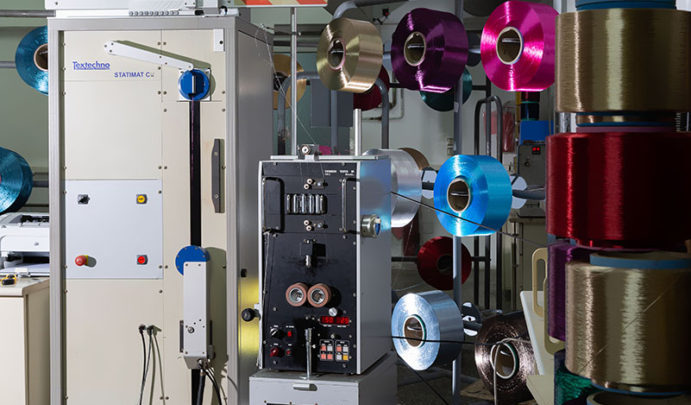

The yarn industry represents 3% of GDP and 27% of the trendy yield. 25% of the industry is centered around creating materials, of which 12% are occupied with home materials, 8% in cotton yarn, and 5% in several materials. The public sector overwhelms the creation business, with half in turning, 60% in stitching, and 60% in weaving. The private sector possesses 90% of the garment side of the business. The turning and weaving area is being overwhelmed by the large scope of companies with a substantial impact on the public sector. In keeping with examination information of 2010, the public sector comprises 3,243 organizations with an absolute venture of 32 billion USD. Egyptian material enterprises produce 315 million clothes and commodities yearly. The US establishes 80% of the country’s trade market, trailed by EU and Arabian nations with 20%. Egypt produces synthetic yarns utilizing excellent POY with global quality standards. Polyester spinners use rapid texturizing machines to deliver mixed/delicate/non-intermixed textured yarns. The Egyptian yarn industry is split into two principal sectors; one is owned and managed by the general public authority, while the private sector claims the other. Since the early 1990s, the private sector has been interested in material creation, yet the public sector controls 91% of the complete Egyptian material production. There are 24 public organizations (large scope) subsidiaries to 1 holding organization, and every organization has an infinite number of production lines.</span   Then again, there are around 100 moderate manufacturing plants related to the private sector; therefore, the remaining plants are small processing plants and a few joint ventures. The number of enrolled private undertakings members of the Egyptian Textile Manufacturer Federation (ETMF) is 2,500, even a sizable number of small production lines and studios that aren’t members of the (ETMF). The textile industry assumes an enormous and influential part in tackling the unemployment issue in Egypt because it provides open positions to the Egyptian working power. The fabric business is viewed as a significant piece in the industry. It is recognized by different integral enterprises which either furnish it with various unrefined components or utilize its items. As indicated by the legislative measurements, almost 33% of the all-out Egyptian assembly business is functioning within the material industry. Moreover, Egypt is one of the countries with low work costs. As indicated by a review published by Werner International Institution, containing the principle material delivering nations of the world, the hourly expenses of the Egyptian laborer were precisely $0.82, $15.78 within the US, $18.91 in Germany, and $2.13 in Turkey.WHO ARE WE?

MIDANI Group for Textiles is one of the leading companies in the textile industry in Egypt. Established in 1960 to create just weaved textures. Afterward, we started delivering colored and printed fabrics. 1990 was a defining moment for “Center East Co. for Textiles,” as it was the year it created synthetic yarn to become a pioneer in this industry in Egypt. To finish the MIDANI Group’s net of progress, the investors funded the build of another plant in 1995, “El MIDANI Co. for Spinning and Weaving,” which was the expected advancement for MIDANI Group, as it produced another item; acrylic yarn, to reach the top in this industry.The last plant, “MIDANI Co. for Man-Made Fibers,” was established in 2006. It’s one of few liquefy-turning plants in Egypt, creating dope-colored POY and FDY Coarse and Fine yarns with typical and miniature fibers in Trilobal and round cross-segment in super-brilliant and semi-dull finishes.

Recently, our yarn factories were ISO 9001 certified, confirming that our manufacturing, facilities, process, and quality are up to the ISO standards! As well-known producers and exporters of yarns, MIDANI Group is determined to supply high-quality products that rival worldwide items, fulfilling client prerequisites and focusing on consistent improvement.